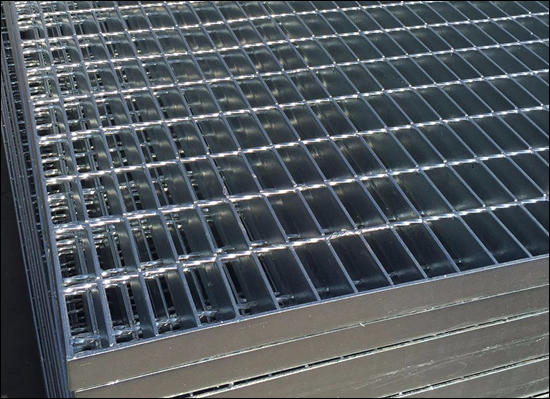

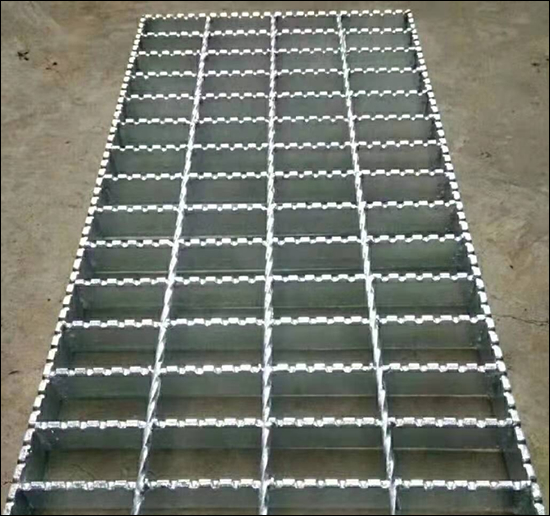

Galvanized steel grating is widely used in offshore oil rig platforms, refineries, walkways and many other industries.

Galvanized steel grating is also written as galvanized iron grating, due to historical naming conventions where the term "iron" was often used to describe various types of steel products.

Gratings Galvanized or Non Galvanized?

Steel gratings galvanized make an better choice over non-galvanized steel bar grating due to the fact that the galvanized coating helps protects the steel from corrosion.

Galvanized Gratings for oil operation platforms are mostly made of heavy welded type steel bar grating heavily galvanised. Steel gratings serrated combined with diamond pattern checker plate are safer and popular stair tread and flooring material for offshore oil platform constructions.

We supply quality galvanized gratings to Europe, Canada, USA, Japan and many other countries.

Galvanized Steel Grating Panels

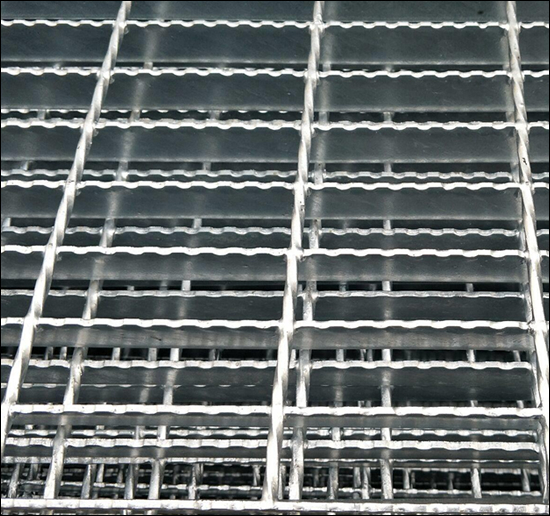

Grating, Hot Dip Galvanized, serrated to BS 4592, Size 19ft x 3ft

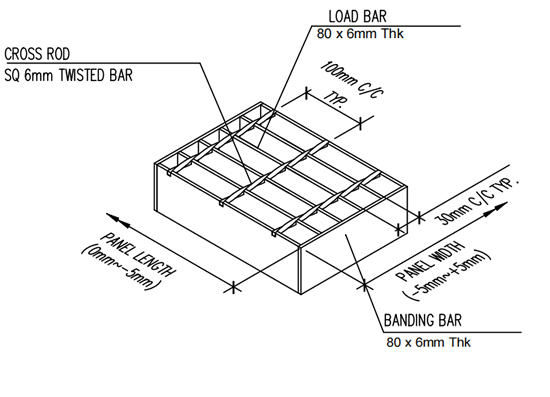

Rectangular pattern with hexagonal or square twisted cross

bars.

- Size of bearing bars: 40mm x 5mm serrated.

- Spacing between bearing bars: 30mm, connected together

with 8mm hexagonal twisted rod every 100mm.

- Top surface of bearing bars shall be serrated.

- Grating panels shall be hot dip galvanized of minimum

460GM/M ^ 2.

- Pitch of cross bars: 50mm.

- Grating suitable for Max. SPAN 67" for 1/4" deflection under uniform working load of 6.6 KN/M ^ 2.

- The grating bar shall be closed end.

Common grating dimensions: 1" x 1/8" x 36" x 24"

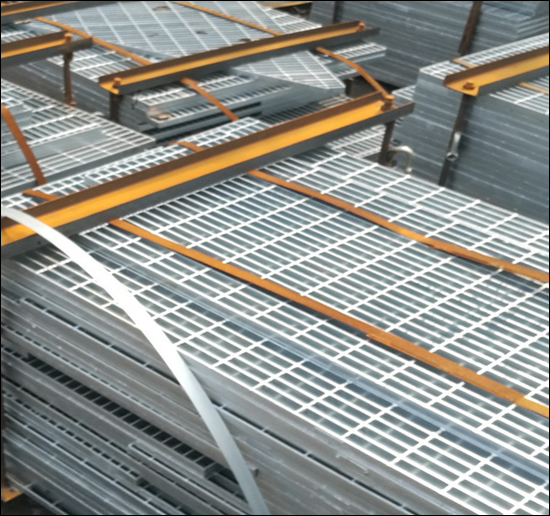

Sheets of Galvanized Grating

Details:

Sheet dimensions:

2400mm load bar length

1200mm sheet width

Thickness: 32mm x 5 Flat bar

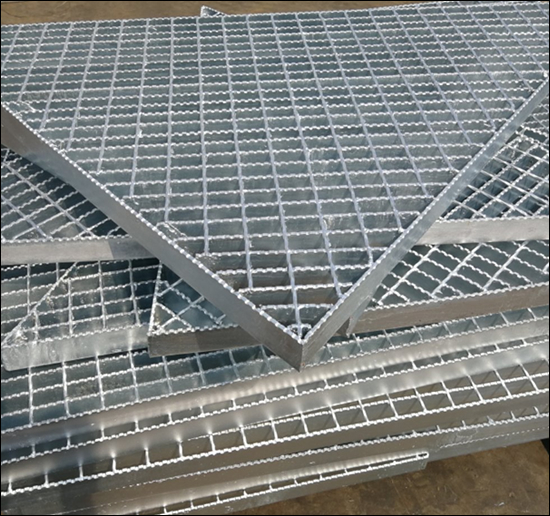

Galvanized Steel Platform Grating -

Grid Safety Mats / Mattress

32x5 - 45kg per square meter, including fastening mat

Galvanized grates 30/5 type, heat galvanized

Grate step: 240x800

Details:

Stair tread with non-slip reinforced nosing

Hot dip galvanized

Mesh: 30x40

Bearing bar: 30x4 including fastening material

Serrated Galvanized Grating

Serrated galvanised grating, with clamp / or clips, 6mm thk serrated bars, 25mm distance between serrated bars (internal), 8mm thk tie rods, 103mm distance between serration ties

Sheet length 6000mm, width 1000 mm x 35mm thickness grating

Galvanized Iron Grating

GI GRATING

Size: 25x6x 905 mmx6m

Galvanized Steel Grating for Construction

Exterior grating, maximum span 10'-6".

Suitable to varying lay-out in construction

Made in accordance with Standard Specifications for Construction:

- Grate dimensions

- Bar sizes and spacing

- Connection details

- Material type

- Coating

- Surface treatment

Materials.

All structural steel shall be Grade 36 or Grade 50. Mill reports for all steel used in the

fabrication.

Grating shall use 2-1/4” (total depth with serrated edge) x 1/4” bearing bars, spaced at 1-3/8”. 3/8”

diameter crossbars shall be spaced at 4”. The grate width shall be 3 feet. Section lengths shall be

sized to end at the center of a 6x6 transverse beams, minimum 18’-9” lengths.

Surface treatment: serrated.

Finish: hot-dipped galvanized.

The connection hardware is hot-dipped galvanized.

Connection method : saddle

clips and 3/8” diameter by 5” long lag bolts.

Construction. Place the galvanized steel grating full length of the span. Assure grating has full bearing on the steel plates

and transverse wood beams. The steel plate has holes to allow for

saddle clip and lag bolt connections.

Removeable Galvanized Grating on Seating Frame

Galvanized grating, removable, 800mm x 800mm x 50mm thk

on 76mm x 50mm x 6.5mm thk seating frame

1 inch x 3/16 inch Galvanized Steel Grating

Details:

Baring bars 1"x3/16"

Min.weight 9.0 lbs.per sq. ft fasten to inlet utilizing pipe sleeves and bolts

Grating panel size:

3’-4” x 4’-10”

2’-0” x 10’-0”

Rectangular Opening Bar Grating, BS 4592 Hot Dipped Galvanised

Grating, open fabric, rectangular BS 4592, hot dip galvanized

Material: Steel

Grating size: 20x3 feet

Standard BS4592

Bearing bars 30mm x 5mm hot dip galvd

Rectangular pattern open steel fabric with hex/twisted square cross bars

Pitch of bearing bars 41mm, pitch of cross bars 50mm

Suitable for max. clear span of 1.5m with 6.0 kn. sqm. safe uni-formly distributed load. material

Compliance certificate & proto-type test (deflection, permanent deformation & collapse)

Coating: Heat Zinc coating

Heavy Duty Galvanized (Hot Dip) Steel Gratings

Size of the grating – 925mm x 1000mm

Square Cross Bar – 10 mm x 10mm

Bearing Plate – 120mm x 6mm thickness

Opening (pitch size) – 45mm x 45mm

2 sides with C Channels, size 100mm x 50mm x 5mm

Fabrication works includes notches/cut-outs

Galv: Hot dip galvanizing after fabrication

Welding specification as per BS EN: 4592

Galvanized Steel Bar Gratings

Sizes:

Resisting side 1310 mm

Mantled side 1695 mm

Open mesh 33x66mm

Side bar 30x2mm

Frame bar on the end of the resisting sides 50x2mm.

Minting Gratings - Galvanized

Rectangular Hole Minting Gratings

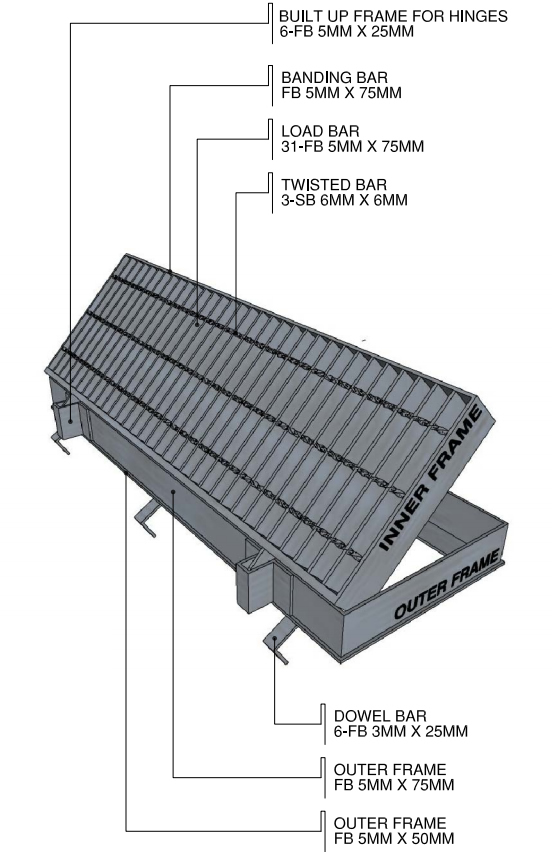

Drawing: Symmetric Grating

Technical details:

Support bar: L2x30x3

Cross bar: 6mm twisted steel

Terminal frame: min. 38mm

Grating fabric: 38x71 mm rectangular

Supporting bar space: 38mm

Cross bar spacing: 71mm

Load: FV 1190KG/m2

Material: Steel, Heavy Galvanised

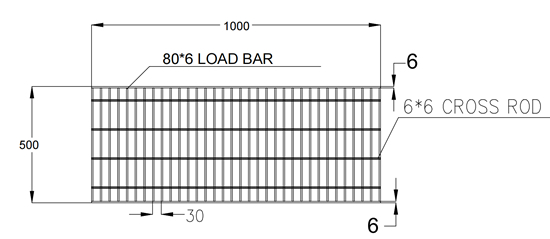

Square Opening Minting Gratings

Frame: 32x3

All support bar, cross bar and side frame are welded

DIN 24535 Industrial Standard

Supporting bar: 1062mm +0/-4

Cross bar: 490mm+0/-4

Fabric: 30x30

Supporting bar material: 32x3

Cross bar material: 6x6 twisted steel

Grating lattice: 32mm height

Material: Steel, Galvanized

Load: 1025 kg/m2

DIN 50976 Hot Dip Galvanized Grating

Grating Panels 960x612mm

Opening: 30x30mm

Supporting rod: 2mm

Cross bar: 2mm

Grating height: 30mm

Material: Steel, Hot Dip Galvanized DIN 50976

Tolerance: RAL-GZ 638

L2x30x3 Serrated Grating

Opening: 30x30mm

Grating height: 30mm

Cross bar: 5mm twisted steel

Material: S235 JR low carbon steel, Hot Dip Galvanized DIN 50976

Tolerance: +0/-4

30x3x6 Galv. Minting Grating

Grating hole: 30x30mm

Support bar: 30x3mm

Cross bar: 6x6mm

Grating panel height: 30mm

Loading: 150kg/m2

Material: Carbon steel, Hot Dip Galvanized DIN 50976

Steel Gratings for Track Hopper Construction for Coal Handling Plant Package in Thermal Power Stations

Drawing reference

Thermal power stations need extensive coal handling and storage. Track Hoppers used for coal handling in power plants are constructed with reinforced cement concrete hopper with metal steel grating covers. All welds applied in grating construction are 6mm thick continuous fillet.

Size:

1950x2420mm

1950x920mm

1438x2420mm

Plat Form Gratings -

for Gas Production Facilities

Platform Gratings and Grating Clip

Material: Carbon steel

Hot Dip Galvanised

Platform grating refer attached drawing NO 9468-VP-SK-35-C-01-B01048/7-C6 rev3

Grating vendor to submit grating drawings for approval before fabrication

Gratings to be hot dip galvanised in accordance with ASTM A 123 or A153

Befor galvanizing maerial shall be fully fabricated, free from all flashes or burrs, with smooth edges, and with all welding complete

Gratings to be 32 * 5 serrated bearing bars & binding bars on 30 NOM centers, c/2 square twisted bars on 100 center

| DESCRIPTION | MATERIAL | SIZE |

| PIPE SUPPORT CLIP | SA516-70 | 221 x 196 x 10 THK. |

| PIPE SUPPORT CLIP | SA516-70 | 284 x 303 x IO THK. |

| PIPE SUPPORT CLIP | SA516-70 | 158 x 467 x ID THK. |

| PIPE SUPPORT CLIP | SA516-70 | 158 x 467 x 1D_TRK. |

| PIPE SUPPORT PAD | SA516-70 | 299 x 110 x 10 THK. |

| PIPE SUPPORT PAD | SA516-70 | 403 x.110 x 10 THK. |

| PIPE SUPPORT PAD | SA516-70 | 467 x 110 x 10 THK |

| PIPE SUPPORT PAD | SA516-70 | 467 x 110 x 10 THK |

| LADDER CLIP | SA516-70 | 209 x 1D0 x 10 THK. |

| LADDER CLIP PAD | SA516-70 | 200 x 100 x 10 THK. |

| LADDER CLIP | SA516-70 | 95 x 100 x 10 THK_ |

| LADDER CLIP | SA516-70 | 146 x 100 x 10 THK |

| LADDER CLIP | SA516-70 | 100 x 100 x 10 THK. |

| STFFNER CLIP | SA516-70 | 131 x 100 x 10 THK. |

| PIPE SUPPORT CLIP | SA516-70 | 100 x 100 x 10 THK. |

| PIPE SUPPORT PAD | SA516-70 | 200 x 90 x 10 THK. |

Platform Ladder Grating and Pipe Clip

Stabilizer Platform Frame and Support

| ITEM | DESCRIPTION | MATERIAL | SIZE |

| 76.01 | FRAME | SA36 | L 75 x 75 x 6 x 8100 LG. |

| 76.02 | FRAME | SA36 | L 75 x 75 x 6 x 3100 LG. |

| 76.03 | FRAME | SA36 | L 75 x 75 x 6 x 4700 LG. |

| 76.04 | FRAME | SA36 | L 75 x 75 x 6 x 1700 LG. |

| 76.05 | FRAME | SA36 | L 75 x 75 x 6 x 6600 LG. |

| 76.06 | FRAME | SA36 | L 75 x 75 x 6 x 2500 LG. |

| 76.07 | FRAME | SA36 | L 75 x 75 x 6 x 4800 LG. |

| 76.08 | FRAME | SA36 | L 75 x 75 x 6 x 1710 LG. |

| 76.09 | FRAME | SA36 | L 75 x 75 x 6 x 3400 LG. |

| 76.10 | FRAME | SA36 | L 75 x 75 x 6 x 1300 UG. |

| 76.11 | FRAME | SA36 | L 75 x 75 x 6 x 1400 LG. |

| 76.12 | FRAME | SA36 | L 75 x 75 x 6 x 1452 LG. |

| 76.13 | SUPPORT | SA36 | C 150 x 75 x 6.5 x 1400 LG. |

| 76.14 | SUPPORT GUSSET | SA36 | 69 x 136 x 10 THK. |

| 76.15 | SUPPORT GUSSET | SA36 | 65 x 150 x 10 THK. |

| 76.16 | SUPPORT GUSSET | SA36 | 195 x 150 x 10 THK. |

| 76.17 | PLATFORM CUP | SA36 | 300 x 190 x 10 THK. |

| 76.18 | PLATFORM CUP PAC | SA516-70 | 400 x 100 x 10 THK. |

| 76.19 | SPACER | SA36 | 250 x 60 x 6 M |

| 76.20 | COUNTERSUNG BOLTS | SA325 HDG. | M16 x 40 LG. C/W WASHER & NUT |

| 76.21 | BOLT C/W NUT & WASH | SA325 HDG. | M20 x 50 LG. (FULL THREAD) |

Notes:

1. All weld to be 6 C.F.W. Unless noted otherwise.

2. Remove all sharp edges, corners & hole burrs.

3. All corner joint to be notched r.25 or Ø12 followed by seal weld all round.

4. Platform structural to be painting as per spec: GL-SP-M-037.

5. Handrail & safety gate surfaces as per ral 1023 yellow.

6. All grating to be hot dip galvanized.

7. Grating as per stadard drawing (main bars 32x5t serrated)

TYPICAL LADDER EXIT ONTO CIRCULAR PLATFORM

Steel Grating Hot Dip Galvanized for UAE

Steel Grating

Drawing Reference:

Bar Details:

Hot Dip Galvanized Steel Grating Serrated, to BS 4592-1

Panels of gratings serrated to bs 4592-1

Size 19ft x 3ft, rectangular pattern with square twisted cross bars

Size of loadbearing bars: 40mm x 5mm serrated.

Spacing (center to center) between loadbearing bars: 35mm

Connected together with transverse bars 6x6mm twisted every 100 mm.

Top surface of bearing bars serrated.

Grating panels hot dip galvanized standard: minimum zinc coating of

460g/mma2

Graiting sutable for max.span 1702mm for 4.34mm deflection under uniform working load of 6.6 kn/m^2

Grating bars have closed ends with binding bars.

Binding bars have the same thickness of loadbearing bars.

SPECIFICATIONS:

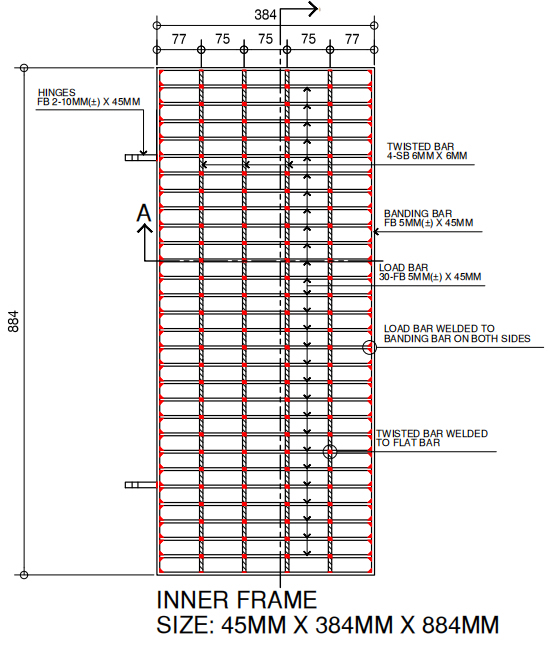

Galvanized Steel Grating Panels with Frames - Framed Gratings

Type One: Grating Inner Frame: Size 45mmx 384mmx 884mm

Grating Outer Frame size: 50mm x400mm x900mm

Grating Inner Frame Details:

Type Two: Steel Grating with Frames and Hinges

Outer frame: size 80mm x 300mm x 1000mm

Inner frame: size 75mm x 334mm x 984mm

Steel Grating with Hinges 75mm x 350mm x 1000mm

Samples of Application Illustration

Galvanized Steel Platform Grating, for Platform and Bridge Walkway

Outdoor metal drain steel grating

Serrated galvanized grating - trench cover mesh grille steel grating

Rivet grating, hot dip galv.

Galvanized Steel Grating Processing and Uses

Galvanized Grating is made by mild steel plate of certain sizes through the processing of grooving, lock-pressure, welding, finishing and other treatment. Industrial bar gratings can be actually made from copper, aluminum and other materials, while galvanized steel grating is the mostly used type due to economic cost and good property.

Galvanized grating / grid with hot-dip zinc coated surface treatment offers good anti-corrosion capacity, shiny surface appearance and durability for uses. It is suitable for places and sites requiring ventilation, widely used in the petrochemical industry, power plants, waterworks, sewage treatment plants, municipal works, sanitation projects in areas such as platforms, corridors, bridge, ditch cover, well covers, ladders, fences, rails, and so on.

Advantages of Galv. Steel Grating:

Galvanised Steel Grating offers the following advantages compared with plain steel grid sheets:

1, Galv. grating has light weight, good strength, durable use and can save materials and cost compared with stainless steel grating or aluminum grating.

2, Galvanised Steel Gratings are designed and manufactured for various industrial and civil constructions in city road, gardens, yard, airport, railway and industrial engineering.

Galvanized Grating Sheet Sizes Available:

863X1000 mm

577X863 mm

863X1000 mm

825X1172 mm

750X803 mm

803X1356 mm

1000X1195 mm

749X1170 mm

1000X1170 mm

622X1170 mm

1000X1182 mm

1182X1376 mm

745X1146 mm

848X1146 mm

1073X1104 mm

788X1104 mm

908X1104 mm

908X1604 mm

1104X1165 mm

688X800 mm

750X1598 mm

210X800 mm

760X968 mm

760X1000 mm

401X760 mm

407X990 mm

637X760 mm

760X1030 mm

1097X2020 mm

1096X2020 mm

560X1498 mm

1092X1178 mm

740X1178 mm

709X1178 mm

702X1178 mm

466X1178 mm

342X1457 mm

626X1178 mm

784X1375 mm

990X1144 mm

TREAPTA 240X800 mm

908X1165 mm

788X908 mm

908X1073 mm

Samples and Data Sheets

We as supplier will enclose detailed dimensional drawings in the technical quotation according to customers requirements.

A sample of the offered steel grating with dimensions of 30x30cm can be provided prior production or delivery as arranged.

The designed weight for each panel is provided in data sheet.

Standards We follow

Chinese YB/T4001.1-2007 or YB/T4001-1998 "Steel grating" standard

American ANSI/NAAMM (MBG531-93) standard

British BS4592-1:1995 standard

Others per customers requirements.

Qindelin Steel Grating Engineering Corporation

Add: New Development Zone, Dezhou, Shandong, China

URL: https://www.steelgrating.org

Email: sale@steelgrating.org